DISCOVER

THE ESSENCE OF CUSTOMIZATION

Show us your brand, and customize literally anything based on your needs.

UNIQUE PERSONALIZATION

Promote team unity and a sense of belonging by creating an unique work apparel.

APPAREL SOLUTION

High level customization gives you the flexibility to select the suitable fabric, design, buttons and cutting - individually.

BRAND STORYTELLER

We have no compromise in details, and we believe even a button can tell your story.

WE ARE NOT YOUR AVERAGE

At Apparel Empire, our vision is to tailor every element of your apparel, ensuring it perfectly reflects your vision and deeply connects with your target audience.

Using our vertically integrated systems, we deliver your custom garments within a reliable 4-6 weeks’ time frame.

CREATE DESIGN

SPECIFICALLY FOR YOUR BRAND

Personalized textures with respective printing techniques that brings up your brand’s identity.

YOUR IMAGINATION IS OUR

Creativity should never be restricted.

This is the reason why we establish our manufacturing facilities and assembled a team of industry experts: to bring ideas into tangible reality.

Ready to tell your brand story through apparel?

We guarantee a solution.

Years Experience

Printing Techniques

Clients Statisfied

Projects Completed

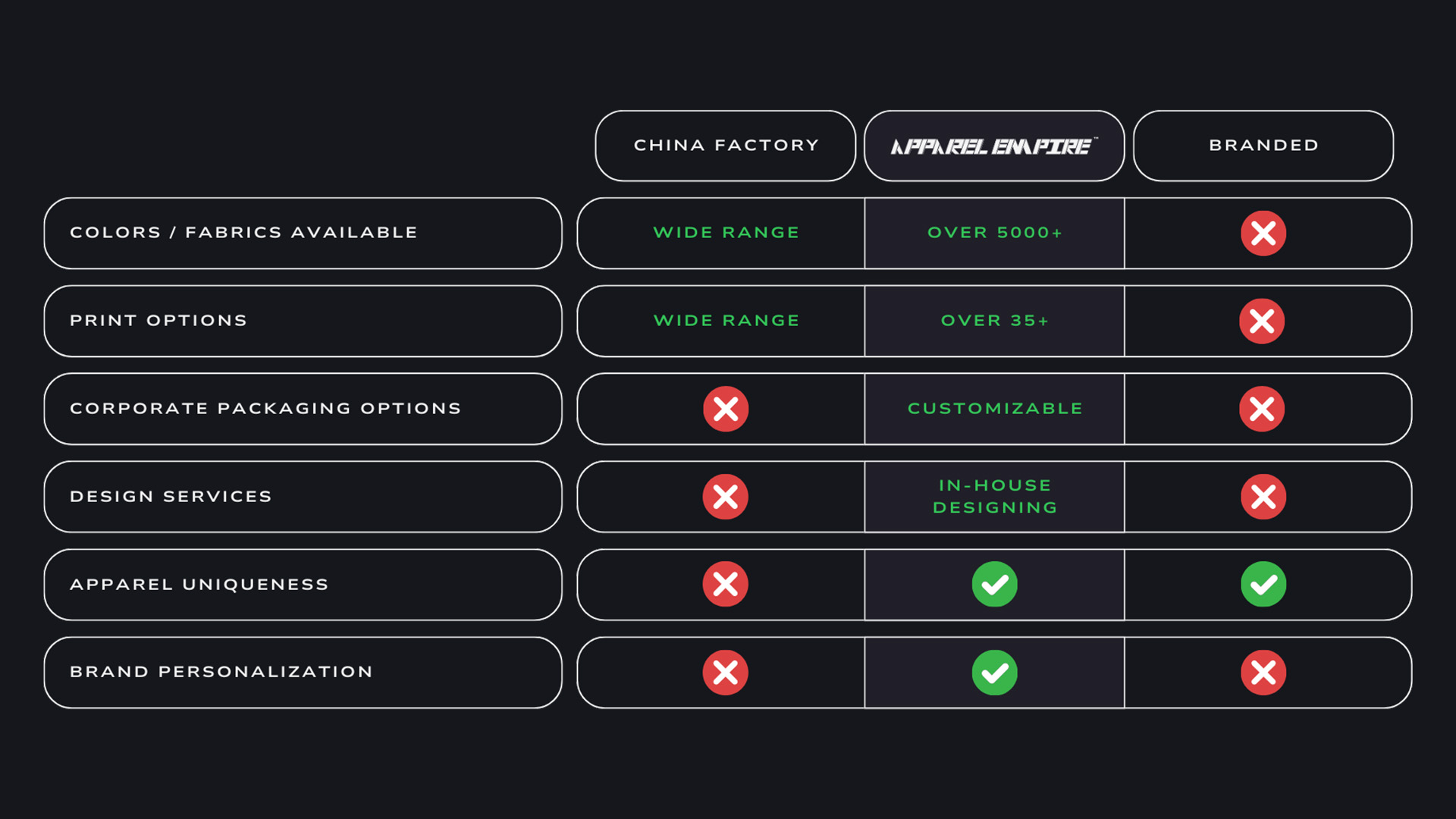

WHY CHOOSE APPAREL EMPIRE FOR

Let every dollar spent be smarter and gain full control of your apparel.

WHY APPAREL EMPIRE CAN PROVIDE

THE BEST

You can conveniently lean back and enjoy additional add-on options and services.

Start building your brand's wardrobe with us today.

TRUSTED BY

We share our clients’ brand’s story across the globe.

TRUSTED BY

With more than 25,000+ Projects completed for companies of all shapes and sizes

CHARLENE KOH

"Your jacket was a huge hit !! Every country streamer loved it so much, they wore it immediately once they got it. Quality is superb. Thanks for rushing it for us !!"

ANTHONY KENNY

"Once again you have done a remarkable job! Thank you for all the work you put into this."

THE HARVARD SHOP

Managing Director

WING SUM

"Ordered for event, the tees was in good quality with reasonable price. Was a great experience working with Frank and Lynn. Defenitely will work with them again and recommend to my friends."

SKECHERS

Assistant Marketing Manager

MS GERALDINE CAITOR

"Hi Joe, seems like your jacket liked by everyone. Now the management want to do for all staff employees, 150 pieces."

KONE

Executive AssistantWE BRING YOUR BRAND IN FRONT OF THE MEDIA